The Power and Precision of TCT Router Cutters: Revolutionizing Woodworking and Beyond

When it comes to precision, durability, and efficiency in woodworking and manufacturing, the tool of choice for many professionals is the TCT (Tungsten Carbide Tip) router cutter. These cutting tools have transformed the industry by offering superior performance, especially in tasks that require intricate detail, high-speed operation, and the ability to handle tough materials. The versatility and longevity of TCT router cutters make them indispensable in a wide range of applications, from carpentry and furniture making to more specialized fields like plastic and metal machining. Understanding how TCT router cutters work and the benefits they offer can help craftsmen and industrial workers alike make the most of this essential tool.

At the core of a TCT router cutter is the tungsten carbide tip, a material known for its exceptional hardness, wear resistance, and ability to maintain a sharp edge over long periods of time. Unlike traditional steel cutters, TCT bits are capable of maintaining their cutting performance even under high temperatures and heavy-duty use. This makes them particularly well-suited for projects that involve tough or abrasive materials. Whether cutting hardwoods, laminates, MDF, or plastics, TCT router cutters provide clean, precise cuts that are consistent and reliable. Their durability allows them to handle the demands of both high-speed routers and CNC machines without sacrificing performance.

The design of TCT router cutters is one of the key factors that contribute to their efficiency. These cutters typically feature sharp, finely honed edges that allow for smooth, clean cuts with minimal resistance. As the tungsten carbide is bonded to the steel body of the cutter, it forms a robust and resilient cutting surface that is far less likely to dull or wear down over time. This is especially important in high-production environments where speed and efficiency are critical. With TCT router cutters, operators can achieve a professional-quality finish with fewer tool changes, reducing downtime and increasing productivity.

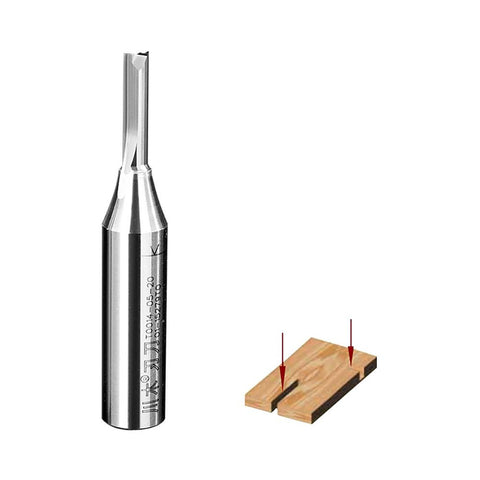

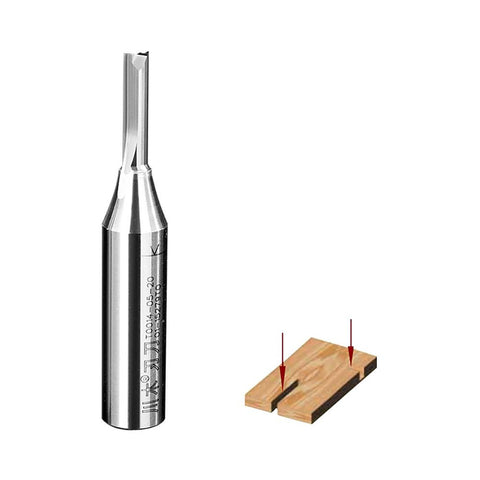

One of the most notable advantages of TCT router cutters is their ability to produce precise and intricate cuts with ease. These cutters are available in a variety of shapes and sizes, each designed to handle specific tasks. For instance, straight cutters are ideal for making precise, clean cuts along a straight edge, while spiral cutters are perfect for making smooth, deep cuts in a variety of materials. For more complex designs, TCT router cutters come in a range of profile shapes, including round-over, ogee, and cove cutters, each allowing woodworkers to achieve a desired finish or decorative edge with minimal effort.

Another important feature of TCT router cutters is their ability to handle high-speed operations without compromising the quality of the cut.

Traditional router bits often struggle under the strain of high-speed rotations, leading to overheating, wear, and reduced performance. TCT router cutters, on the other hand, are designed to maintain their sharpness and structural integrity even under the most demanding conditions. This makes them ideal for high-speed machining tasks, where the router is running at full capacity for long periods of time.

In addition to their durability and precision, TCT router cutters offer an extended lifespan compared to other types of router bits. Tungsten carbide is a much harder material than high-speed steel, meaning TCT cutters are less prone to wear and tear, even when working with dense materials. This longevity is particularly beneficial for businesses or hobbyists who rely on their tools for frequent, high-volume projects. The ability to maintain a sharp cutting edge for longer periods of time also means fewer replacements and less maintenance, saving both time and money in the long run.

TCT router cutters are also known for their versatility. Not only are they effective on wood, but they are also capable of handling plastics, aluminum, and other non-ferrous metals. This adaptability allows manufacturers and craftspeople to use a single tool for multiple materials, reducing the need for specialized cutters and simplifying tool management. This versatility makes TCT router cutters invaluable for industries such as cabinetry, furniture making, sign-making, and even metalworking, where precision and speed are crucial.

For those working with particularly tough or dense materials, TCT router cutters offer the ability to make deeper cuts with greater control. Their strength allows them to handle demanding tasks like creating grooves, profiles, and dadoes, all while maintaining a high level of accuracy. TCT bits can also be used to perform challenging operations, such as cutting through laminated surfaces without chipping or causing damage to the material beneath. This reliability ensures that the finished product is of the highest quality, free from imperfections or rough edges.

While TCT router cutters offer numerous benefits, it's important to use them properly to ensure optimal performance. Proper maintenance, such as regular cleaning and sharpening, is crucial to keeping the cutter in top condition. However, even with minimal maintenance, TCT router cutters can significantly extend the lifespan of the tools and provide consistent performance over time. Whether working with wood, plastic, or metal, the investment in TCT router cutters is one that pays off in terms of both quality and efficiency.

In summary, TCT router cutters have become a staple in modern woodworking and machining due to their exceptional durability, precision, and versatility. These cutters allow users to achieve clean, accurate cuts in a wide range of materials, all while minimizing wear and maintaining a high level of performance over time. Whether for industrial production or DIY projects, TCT router cutters enable both professionals and hobbyists to complete tasks with greater speed and precision, making them an invaluable tool for anyone seeking to elevate their craft or streamline their operations.